Hello Fiber Arts Friday Fans! It’s been a while since I’ve done a science behind alpaca fiber so here we go. Today’s question, why is alpaca warmer than wool?

What is Alpaca Fiber?

Well all know that fiber from a sheep is called wool and the stuff that we wash and comb on our own heads is called hair but what is alpaca? The argument can be made that alpaca fiber is really a hair but is often referred to as wool but for the majority of breeders we refer to it as, fiber.

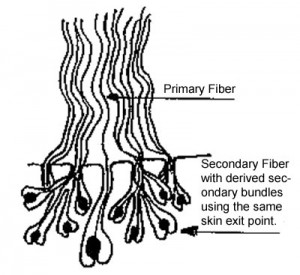

The fiber that is sheared from the alpaca is produced by primary and secondary hair follicles and even a derived secondary which grows in both the primary and secondary follicles.

Primary fibers are what we call guard hair and are straight and stiff often giving that prickly sensation next to the skin. These fibers are most present on the legs and brisket of the alpaca and sometimes can be seen as a halo above the finer secondary undercoat or are called “cria tips” on new born alpacas.

Secondary fiber is the soft undercoat that gives the alpaca a soft handle. Secondary fibers cluster around a primary follicle and are the fiber that creates the crimp. Note: You cannot have secondary or derived secondary fibers without a primary fiber, therefore breeding to eliminate primary fiber results in a low density high micron fleece. Surprisingly, as fiber density increases the diameter of primary fibers decreases as it is forced to share skin real estate with secondary and derived secondary fibers.

Derived Secondary fibers are the finest of the 3 types and are what breeders strive for. A derived secondary follicle has its own root structure but share the same exit point from the skin of a secondary fiber. This type of fiber can only be identified through a skin biopsy.

Alpaca Fiber Structure:

Alpaca fiber is made up of 3 different parts, Cortical Cells, Cuticle, Intercellular Binder.

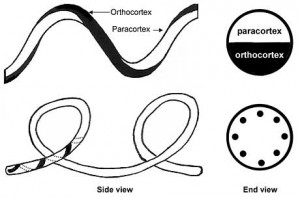

Cortical Cells – These are the body builders of the fiber and give it strength along with creating the crimp that we love so much. What causes crimp? Cortical Cells are made up of 2 parts, the orthocortex and paracortex. These 2 parts twist around each other creating the crimp in Huacaya or the twist in a suri. This crimp causes the actual fiber length to be 10%-30% longer than the staple length. Unfortunately crimp is not a reliable when determining fineness.

Cuticle – to protect the cells each fiber is covered in a material that we often refer to as scale. This protective coating is what provides the fiber its strength and also makes the fiber smooth to the touch. This is what we feel when we check for handle in a fleece as we rub the fibers between our fingers. The scale is also reflective and produces luster.

Intercellular Binder – It’s the glue that holds the 2 cell parts together within the cuticle.

Findings:

Alpaca owners who have been telling others this fess up, “alpaca fiber is warm because it is hollow and traps air for extra insulation.” I heard this from several breeders and never really questioned it until now.

The only medullated (hollow) hair fibers are the thick prickly guard hair which none of us wants in our fiber. So what causes alpaca’s superior warmth? The simple answer fineness and density. Alpaca fiber is finer, allowing more hairs to occupy the same space, more fiber = more trapped air = warmer.

Example Wool vs Alpaca

Let’s take a typical worsted weight yarn. The memory of wool causes the yarn to look fluffy and springy and less fibers are needed to occupy the space for a worsted weight yarn. The alpaca yarn does not have memory, is finer and requires many times more strands of fiber to occupy the same space needed to make a worsted weight yarn. (I keep hearing it’s about 3x more but have not found research to back this yet).

Because dense fine alpaca fiber weigh less than wool, lighter weight yarns and garments can be made from alpaca that have the same or superior insulating properties to thicker wool garments.

UPDATE 8/13/11: According to the Yocom-McColl Wool Testing Labs alpaca fiber is NOT medullated (hollow) but most fibers DO have a trapped air bubble within the fiber! Check it out! The dark bubble in the center of the fiber is trapped air.

Thank you and this concludes today’s Fiber Arts Science Friday 🙂 Be sure to check out the link-parties page!

References:

Elite Alpaca Breeding Systems

SRS Alpacas International