Whether you’re thinking starting an alpaca farm or are a seasoned rancher the question is always the same. What do you do with all that fleece?! I’m surprised to find that many folks shear it, bag it, and store it without doing anything at all. (FYI Fiber does have a shelf life).

Whether you’re thinking starting an alpaca farm or are a seasoned rancher the question is always the same. What do you do with all that fleece?! I’m surprised to find that many folks shear it, bag it, and store it without doing anything at all. (FYI Fiber does have a shelf life).

Since many folks frown upon eating alpacas the only ways to cover your cost of ownership of these animals is to sell fiber, products or breeding stock. Yes, you CAN make your alpacas pay for themselves with fleece sales but only if you manage your farm properly.

Alpaca ownership is first and foremost a business. As with any business you have to realize what your costs are and work on lowing them to realize a profit. Here are the key factors:

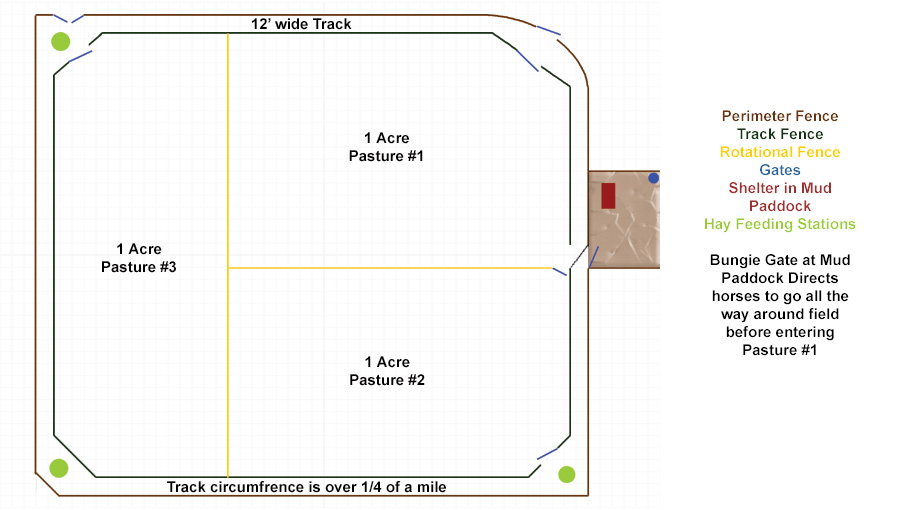

- Location: Alpacas eat grass which for the most part is free! That is unless you live in an arid climate then you have to spend $$$ on hay. Money spent on hay is money out of our pocket. My alpacas are grass fed 6-8 months out of the year. Yippy, FREE food!

- Feed: There’s no substitute for good pasture management. A good pasture with quality forage is everything that an alpaca needs to thrive. I do not grain my alpacas unless I have a pregnant dam that is skinny and needs help maintaining weight. For 6-8 months out of a year I am able to “feed free” so to speak on quality pasture alone.

- Supplements: Since the pasture is supplying all of the feed it is important to know what vitamins and minerals you may be lacking. Soil samples will help you decide what to supplement. We are low in selenium in my neck of the woods and I’ve opted to offer free choice Dumor Sheep Mineral to all of our alpacas since it contains the minerals I need at a very affordable cost.

- Water: Offering quality fresh clean water to drink is another key. Keep your animals hydrated especially in the winter. Heated buckets in winter are a MUST. Hay is dry and alpacas need water to help the digestion process. Alpacas will not drink enough water if it is frozen or ice cold. The cost of running a heated bucket is minimal to what a vet visit will cost you should they colic or become anemic.

- Worming ,Vaccinations, General Health: You can save $ by giving shots yourself but in some states (like NY) only a veterinarian can give rabies shots. Also learn how to clip toenails, trim teeth, run fecals, do blood draws, etc yourself. The more you empower yourself the less you pay your vet.

- Shearing: Finally, what does it cost you to get the fiber OFF the alpaca?

Calculating Cost per Pound and Ounce:

Most of us will sell fleece by the ounce or by the pound so when you’re figuring your costs you want to know what your costs are in terms of costs per ounce or costs per pound of fleece. I narrow this down to what it costs to care for 1 alpaca per year. That way when I weigh out the usable fleece I know what that alpaca costs me in terms of fleece weight!

Here are my 2010 and 2011 calculations for yearly cost per alpaca. Last year I had a herd of 9 this year I’ll be up to 16. In most cases the cost of care per head goes down with more animals you own.

2011 Projections (2010 in RED)

6 months Grass: $0

6 months Hay: $17.5 ($33)

Grain: $7.5 (same)

Minerals: $1.25 ($2.5)

Syringes: $2.5 ($3)

Wormer: $6.5 ($10)

Rabies: $2.25 ($21)

Heated Water: $1.25 ($2.20)

Summer Fans: $1.25 ($2.20)

Shearing: $5 ($30)

Teeth: $0.25 ($10)

Misc Vet: $10 (same)

———————————-

Total: $55.25 ($123.90)***

***This is the cost to care for 1 alpaca on our farm per year. This does NOT include other factors of running a business like property tax, gas, hardware, equipment, travel, etc. I include those factors in my Mark Up % when pricing products since I retail more than just alpaca fiber. Read More About Pricing Products Here

So what does 1 ounce or pound of fiber cost you? Co-ops, commercial mills, and other companies that purchase your fiber will only want the best quality. Outside of breeding for better fiber it is very important to handle it properly after shearing to maximize your yield. Skirt the fleece removing all large vegetable mater, discolorations and guard hair. Then bounce on table or tumble to remove small debris and dirt. Dry your fleece in an open bag next to a dehumidifier for 24hrs before weighing.

This clean dry weight is your prime sellable fleece. I’ll typically get 3 to 6 pounds of high quality fiber per alpaca. For the purpose of this exercise let’s use the average of 4.5lbs. For comparison the average sheep will produce 7.5lbs of fiber but 40-50% of that weight is grease.

Prime Raw Fiber

4.5lbs = $55.25 ($123.90)

4.5lbs = 72 oz

Cost per oz = $0.77 ($1.72)

Cost per lb = $12.28 ($27.53)

As you can see small changes in your heard management practices can make a big difference in your bottom line. Here are the changes we are making to lower our costs from 2010 to 2011

6 months Hay: Moving from feeding small square bales to large rounds

Rabies: vaccinating whole herd vs only those that are traveling (required by NYS)

Shearing: Cost of me shearing vs hired shearer

Teeth: Cost of me trimming teeth vs hired shearer

Processing and Selling Your Fiber

Most people do not buy fiber from you in the “raw” state but are more apt to purchase fiber as roving or yarn so let us also look at those costs (less shipping).

Cost/lb at a NY mill (total with costs added from above)

Roving/Bat = $12.50 ($24.78 $40.03)

Pin Drafted = $15.50 ($27.78 $43.03)

Yarn = $26.75 ($39.03 $54.28)

Cost/oz at a NY Mill (total with costs added from above)

Roving/Bat = $0.78 ($1.55 $2.50)

Pin Drafted = $0.97 ($1.74 $2.68)

Yarn = $1.67 ($2.44 $3.39)

Fiber Pools and Co-ops

Another outlet for your fiber is to send it off to fiber pools or co-ops. At these places your fiber is combined with those of other farms into large commercial runs for products like socks, hats, yarn, blankets etc. These pools and co-ops willthen allow you to purchase product back at or below processing costs and in some cases will pay dividends back to their member in profitable years. Examples: NEAFP and AFCNA

Alpaca Blanket Project

This company started a few short years ago and has grown considerably. They are now able to offer up to $5 per pound for your raw fleece. Members can also purchase blankets back at a discounted rate.

Selling to Mills Directly

Many small cottage mills will purchase alpaca fiber directly but at a price/lb.

Large production commercial mills have also started purchasing alpaca fiber from North American ranchers but only beige or white fleeces. I know alpacas come in 22 different colors but it is the light colored animals that will be called for in commercial production. If you don’t believe me visit the herds in Peru some time…. All beige and white.

Scrap Fiber

All the calculations above are based on “commercial” prime quality fiber; fiber that you can sell to mills and manufacturers directly. However, a typical alpaca will yield 9-14 pounds of fiber over all so what to do with all the other fiber? I consider sales of this fiber to be a bonus and there are MANY outlets for it, here are some of the things I do with my neck, leg, and belly fibers.

Rugs and Rug Yarn – Mills are now offering rug weaving and rug yarns. Mix up a bag of skirted scraps (2” or longer) for a colorful rug yarn that can be woven, crochet or knit into soft bath mats or have the mill make the rugs for you.

Felt – Purses, bags, hats, coasters, rugs, pillows, dog beds, comforters, artwork and more. Wet felting fabric yourself or having the mill do it for you can open up a whole new world of possibilities. Be creative!

Stuffing – We all have the “garbage” bag where all the shorts and swept up scraps go to die. This too can be used. Fill up suet feeders or chicken wire cage with fiber scraps as a nesting feeder for spring birds. Wash and dry scraps to remove smell and use these unsavory pieces to stuff dog toys. My dogs go NUTS for alpaca stuffed toys.

Conclusion:

As the inflated price of alpacas comes down to sustainable levels the majority of alpaca farms will soon be looking to cut costs and breed for fiber profitability. With hard work, conservative planning, artistic ability, marketing and salesmanship; the cottage and commercial future of alpaca fiber will thrive.