Welcome back to FAF. I hope you have your learning caps on because I’ve been digging into the research again.

This time I wasn’t sure what I was looking for but ended up getting all angry at today’s alpaca industry. Long story short? Why is it in the late 1800’s there was a perfectly sustainable alpaca fiber industry in the US without a single alpaca on American soil, yet today there are all these co-ops, registries, organizations and still we’re not getting paid for our fiber raised right here in America? ARGH. Ok rant done.

If you’ve read my post about Abraham Lincoln you’ll know that alpaca was his favorite textile but what happened to that thriving industry? As it turns out around 1865 alpaca fiber was brought to the US and there was a very demanding market for 12 years. 2 alpaca mills were even established in Massachusetts, one in Holyoke and the other in Lawrence and specialized in linings, yarn, and dressed goods.

During its heyday, there was more demand for alpaca than there was availability and in 1875 the first alpacas were brought to the US and resided in the Alleghany Mountains in Maryland. Unfortunately, as soon as the alpacas got here the demand for their fiber fell. I guess the trends of the day changed and consumers were after luster deprived fabrics, yuck.

The small herds of alpacas in Maryland were not doing very well either. The lush grasses and atmospheric conditions were thought to be the culprit. If I had $ to bet I’d say it was the M-worm that took its toll on the flock. The high elevations of the Rockies was thought to be the only place where alpacas would ever survive in the country.

At the time of the writing of the article (1883) there wasn’t a single alpaca living from the 1875 import. Thankfully, in 1883 another interest by consumers for alpaca was re-awakening and experiments blending alpaca with silk were showing to be favorable. The author made assumptions that with renewed interest and new favorable locations in Wyoming and Nevada that alpacas would be prominent in America and would rival that of the merino sheep industry.

Well I guess we both know that the US now days is known neither for its thriving alpaca fiber industry nor is it the world leader for merino sheep. *sigh*

Other than bookworming I’ve been happily working away doing fibery things. Unfortunately I’m not using alpaca in my projects?! Why? Because it takes between 8-14 months for my fiber to get back from the mill! It’s been so long that I don’t even remember what day let alone month I sent my fiber to the mill. (Seriously rant over I promise)

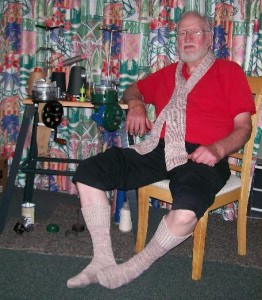

I have been working on a baby blanket for a friend of mine and my sock yarn shawl for another. I also picked up some beautifully green yarn on sale at Joann’s. Ok I know, its Joann’s but I had a 10% off my entire order coupon and the yarn was on clearance too.

What have you been up to? Be sure to check out these other Fiber Folks.

Encyclopaedia Britannica 1888